Have you noticed how furniture edges start to chip or peel over time? It’s not just about looks—it’s about durability! Edges of furniture have the most impact, so they’re prone to damage. That’s where edge band tape comes in as a lifesaver.

This simple yet mighty material protects exposed edges from moisture, scratches and everyday wear. Whether it’s kitchen cabinets, office desks, or wardrobes, edge band adds strength while adding style.

This post will explore how edge bands extends furniture life and why it’s a must-have for long-lasting interiors. Are you ready to keep your furniture looking perfect for years to come?

Let’s get started!

What is an Edge Band Tape?

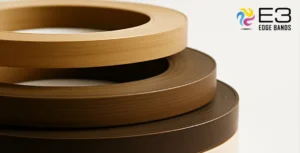

Furniture edges get chipped, water damaged and worn out over time. Edge band is the answer to protect and finish these exposed surfaces. It’s a thin, tough strip applied to the edges of wooden furniture to add strength and a seamless finish.

Types of Edge Bands

PVC Edge Banding Tape: Flexible, affordable and very durable, good for all types of furniture.

Acrylic Edge Banding Tape: High gloss finish that makes modern interiors pop. Furniture Edge Banding Tape: For added protection and longevity, so furniture looks new for years.

Beyond durability, edge band tape adds aesthetics so that furniture looks polished and professional anywhere.

How Does Edge Bands Prevent Wear & Tear?

Furniture edges are subject to wear and tear from daily use, moisture exposure, and accidental impacts. Over time, this can lead to chipping, swelling, and scratching, which makes furniture look old and worn out. Edge band tape is a protective shield with durability and style.

Let’s see how it prevents damage and extends furniture life.

1. Moisture Protection

Edge tape for wood seals exposed edges, preventing water absorption that can cause swelling and warping. Furniture in humid environments like kitchens and bathrooms is prone to moisture damage. Still, PVC edge banding tape creates a waterproof barrier. It prevents long-term damage by blocking humidity from seeping into the core material.

2. Scratch & Impact Resistance

It lessens the likelihood of furniture chipping, dents, and scratches as well as damage from unintentional bumps. High-traffic areas like wardrobes, office desks, kitchen cabinets, and study tables for kids benefit from it.

3. Enhance Durability

By placing an additional layer of protection, you can strengthen the edges of your furniture and reduce the likelihood that any external pressure will cause damage. Furniture edges are maintained and long-lasting durability is provided by acrylic edge banding tape. It stops furniture from peeling or cracking, which happens frequently when edges are not properly sealed. Furniture value is maintained because the edges stay strong, smooth, and undamaged.

Types of Edge Banding Tape for Furniture

Selecting the right edge band tape is most important for durability and looks. Different types of edge banding cater to varying needs, whether regarding flexibility, a modern look, or seamless blending with wood surfaces.

Let’s look at the top three types used in furniture manufacturing.

1. PVC Edge Banding Tape: Flexible, Affordable and Widely Used

They are much in demand to be used as furniture edge banding tape because of their cost-effectiveness and durability. Made from polyvinyl chloride (PVC), this tape is very flexible and easy to apply to curved edges. It is available in various textures, colours, and finishes to match different furniture styles. These tapes are moisture, chemical, daily wear and tear-resistant, making them ideal for kitchen drawers & cabinets, bathroom cabinets, wardrobes, and office furniture.

2. Acrylic Edge Band Tape: High Shine for a Classy Finish

Its high-gloss mirror like finish makes it perfect for modern interiors. The seamless, glass-like finish gives the furniture an elegant look. It is sturdier than PVC edge banding tape and is better scratch—and impact-resistant. UV-resistant colours don’t fade over time, making them ideal for luxury furniture designs. It is also perfect for modern kitchens, office desks, and high-end home interiors requiring a polished look.

3. Edge Tape for Wood: Blends with Wood Surfaces

It is designed to match wood grains and is perfect for wooden furniture and cabinetry. It has a real wood-like appearance while protecting edges from chipping and peeling. It is used for premium furniture where aesthetics is as important as durability. It is available in multiple wood tones, textures, and finishes to match it with solid wood, MDF, or plywood furniture.

Choosing the Right Edge Band for Your Needs

Selecting the perfect edge band tape is key to the durability and aesthetics of furniture. With various materials, colours, textures and adhesives available, choosing the right one ensures long-lasting performance and a seamless finish.

Here’s what to consider:-

1. Factors to Consider

Thickness:

Thin edge band tape (0.4mm – 1mm) for light-duty furniture like office desks and shelving units.

Thick edge band (1.5mm – 3mm) for heavy-use furniture like kitchen cabinets and wardrobes for better impact resistance.

Colour & Finish:

Match the colour and texture with your furniture for a seamless look.

Matte, glossy and textured finishes are available.

Acrylic edge banding tape for a high-gloss modern look; wood-grain edge tape blends in with wooden furniture.

Texture:

Smooth PVC edge band tape for a modern, sleek interior. Embossed or textured options for classic and rustic interiors.

Adhesive Strength & Durability:

Choose edge banding with high-quality adhesive to prevent peeling over time. Heat-resistant and moisture-proof options for kitchens and high-humidity areas.

Best Edge Band for Different Furniture

Kitchen Cabinets:

PVC edge banding tape is the top choice due to its moisture resistance and durability. Glossy acrylic edge banding for modern kitchen designs.

Wardrobes & Closets:

PVC edge tape is used to prevent chipping and to protect the edges of furniture and extend its life. Wood grain: keeps the look of natural wood.

Office Desks & Workstations:

For high-end work environments, acrylic edge banding tape gives a premium appearance. Scratch resistant edge band tape can use day by day.

Shelving Units & Storage Racks:

For lightweight shelves, use thin PVC edge tape. Use sturdy edge tape with an adhesive backing for high-traffic areas.

Final Words

Edge band tape is not just a finishing touch—it’s a protective shield that makes your furniture more durable, beautiful and long-lasting. Whether you choose PVC edge banding tape, acrylic edge banding tape, or wood edge tape, investing in high-quality material will resist moisture, scratches and daily wear & tear.

Ready to upgrade your interiors with premium edge band tape? Go E3 Edge Band—where quality meets perfection!

Is your edge banding tape peeling off and ruining the look of your furniture? Don’t worry—you’re not alone! Heat, moisture or improper application can cause edge banding to lift and peel. But the good news is you don’t have to replace it entirely!

With the proper techniques, you can fix your furniture in no time. Whether a slight peel or complete detachment, this will help you determine the cause and apply the best fix.

From DIY hacks to professional fixes, we’ll cover everything you need to reapply, repair and prevent peeling edge banding. Let’s get started and get your furniture looking like new again!

Why Does Edge Banding Tape Peel Off?

Edge banding tapes improve the durability and look of furniture, but peeling can ruin its function and appearance. Here is why PVC edge tape starts to lift or detach over time.

1. Bad Adhesion

If the edge banding tape isn’t applied correctly or the adhesive is low-quality, it won’t stick well to the surface. Over time, this leads to lifting and peeling, especially along frequently used edges.

2. Heat & Moisture Exposure

Furniture near humid areas or near heat sources, such as kitchens and bathrooms, is more prone to PVC edge tape peeling. Heat weakens the adhesive, and moisture seeps in and reduces its grip.

3. Wear & Tear

Edge banding tapes can loosen due to daily use, friction, and impact. High-traffic areas like cabinets, desks, and countertops experience more stress, which can lead to gradual detachment.

4. Low-Quality Material

Using cheap or low-grade edge banding tapes will result in a shorter life span. Choose solid series edge banding for better durability, stronger adhesion and resistance to environmental factors.

Quick Fixes for Peeling Edge Banding Tape

Peeling edge banding tapes can make furniture look old, but the good news is—it’s fixable! Whether a small lift or a complete pull-off, here’s how to quickly fix your edge banding PVC tape.

A. DIY Fixes for Small Peeling

Hot Iron – Place a cloth over the peeling edge, banding PVC tape and iron. The heat will reactivate the adhesive and stick it back in place.

Super Glue or Contact Cement For a stronger bond, put a thin layer of super glue or contact cement under the lifted section of solid series edge banding and press down until it sticks.

B. Fixing Fully Detached Edge Banding

Remove Old PVC Edge Tape – If the tape has come off, clean the surface to remove any leftover glue or debris for a smooth reapplication.

Reapply with New Adhesive Choose a good-quality adhesive for edge banding PVC tape. Apply it evenly, press the tape, and use a roller or heat gun for a perfect bond.

Stopping Edge Banding Tape from Peeling Again

Fixing edge banding tapes is one thing, but ensuring they don’t peel off for years is even more critical. Follow these steps to prevent peeling and extend the life of your PVC Edgeband tapes.

1. Choose High-Quality Edge Banding Tapes

Not all edge banding tapes are created equal! Investing in solid series edge banding is better, stronger, faster and longer-lasting. Cheap ones will weaken over time and peel off.

2. Apply the Right Heat & Pressure During the Installation

Always use the right temperature and pressure when applying edge banding PVC tape for a strong bond. A heat gun or an edge banding machine will give you even adhesion and reduce the chances of early lifting.

3. Protect from Warm & Damp Conditions

Too much heat and moisture can weaken the adhesive bond. Keep furniture with PVC Edgeband tapes away from direct sunlight, stoves or damp areas. Using sealants or edge protectors will give you an extra layer of protection.

When to Replace Edge Banding Tape?

Even the best edge banding tapes have a life span. While minor peeling can be fixed, some signs show it’s time for a complete replacement. Here’s when you should replace your old PVC edge tape with a new, durable one.

1. Signs of Irreparable Damage

Deep Cracks or Chips—If your edge banding PVC tape has cracks, it’s beyond repair.

Discolouration or Fading—UV exposure will make PVC edge tape lose its colour over time.

Repeated Peeling Issues—If the tape peels even after fixing, the adhesive has worn out.

Rough or Warped Edges—Warping means exposure to too much heat or moisture, so replacement is necessary.

2. Best PVC Edge Tape for a Fresh Look

When replacing edge banding tapes, choose a solid series edge banding for durability and a seamless finish. Look for:

UV-coated tapes to prevent fading

Moisture-resistant PVC edge tape for kitchens and bathrooms

Perfect colour match for laminates and furniture

How Can E3 Group India Be of Assistance?

E3 Group India is the company to trust for edge banding solutions. They have years of experience in manufacturing and R&D. Regarding quality, innovation, and durability, E3 Group offers various edge bands that enhance aesthetics and functionality.

1. PVC Edge Bands—Flexible & Strong

E3 Group’s most extensive range of PVC edge banding is designed to be flexible and strong. These edge bands match all available laminates and have top-quality features like moisture, heat, and impact resistance.

2. Soft-Touch Edge Bands—Luxury at Your Fingertips

For a premium feel, E3’s soft-touch edge bands provide a velvety texture that adds luxury to high-end furniture. These edge bands add strength, enhance looks and increase the durability of the furniture by protecting it from daily wear and tear while contributing to a visually appealing piece of furniture.

3. Fluted Edge Bands—Unique & Decorative

E3 Group brings innovative creativity with fluted edge bands, perfect for modern interiors. These elegant edges give furniture pieces depth and substance while giving them a distinctive, contemporary look.

4. Acrylic Edge Bands—Glossy & Impact-Resistant

E3’s acrylic edge bands have a high-gloss, glass-like finish, perfect for premium furniture. They are durable, UV-resistant and modern-looking.

5. ABS Edge Bands—Environment-Friendly & Strong

E3 Group offers 100% recyclable, firm, chemical—and wear-resistant free ABS edge bands for sustainability without compromising quality.

Connect with us today and give your furniture a new look!