The process starts with the selection of high-quality PVC resin and additives.

The selected PVC resin and additives are mixed together in a compounding machine. This process ensures that the additives are evenly distributed throughout the PVC material.

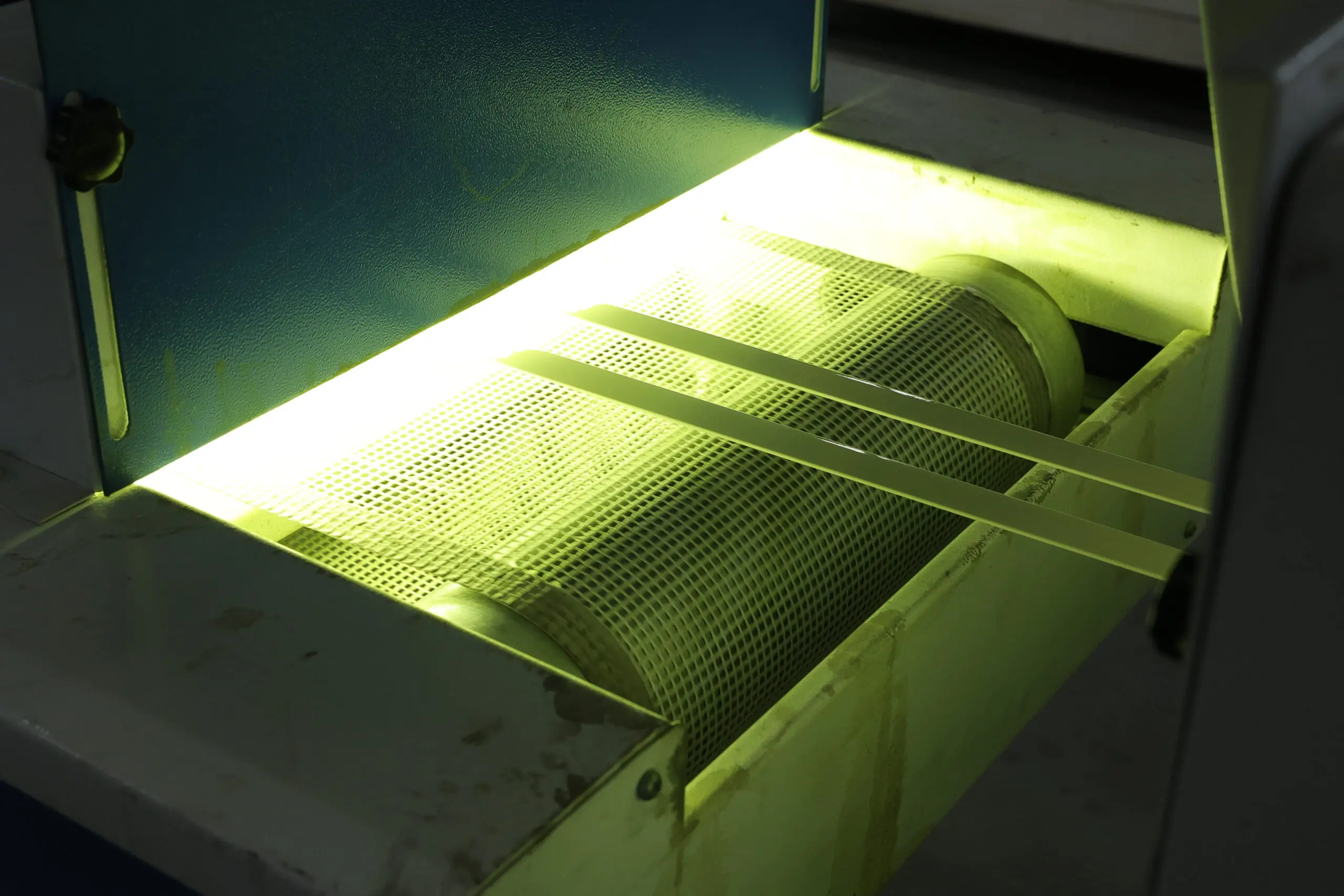

The compounded PVC material is then heated to 200 degree celsius and forced through an extrusion machine, which shapes it into the desired profile.

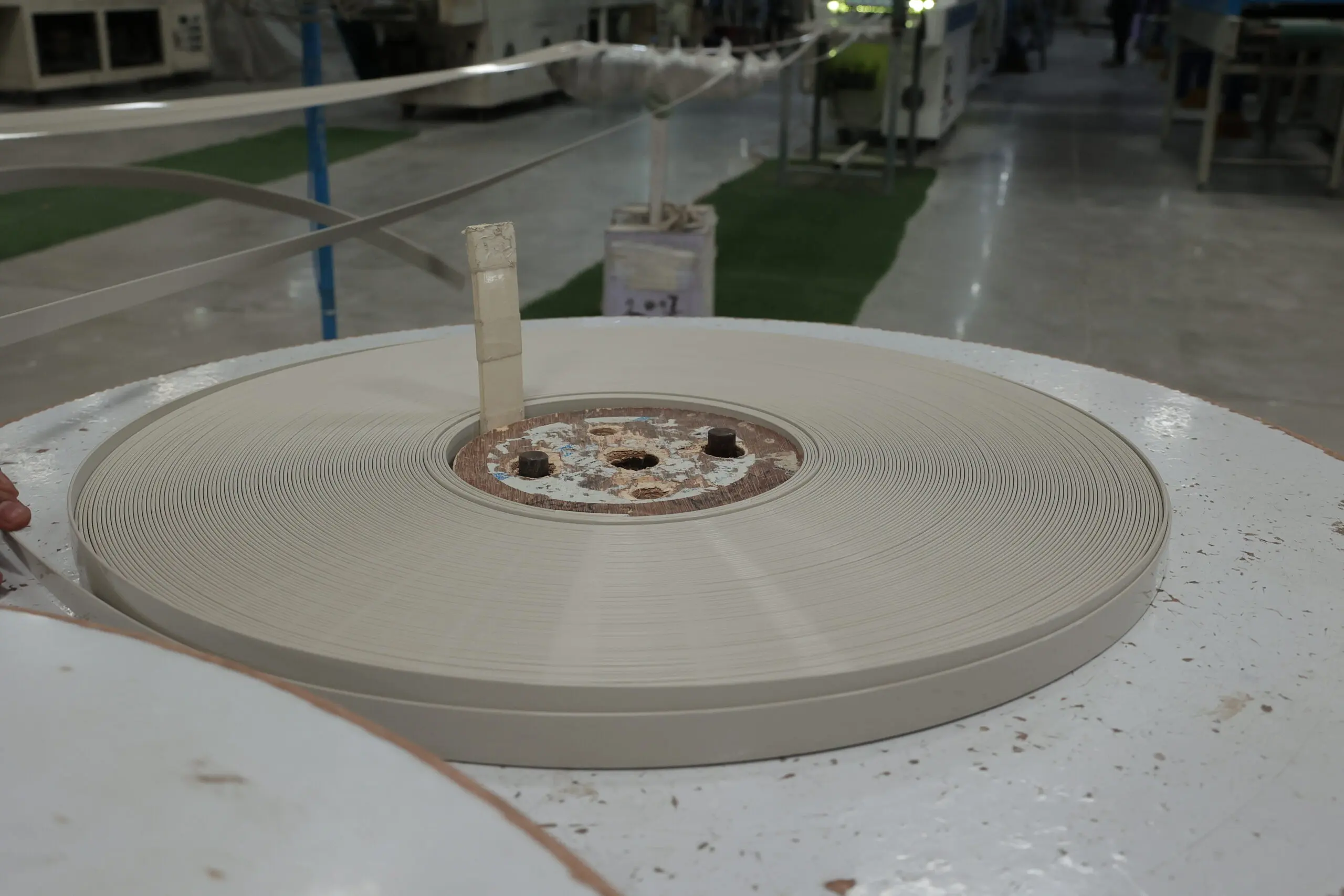

After extrusion, the PVC edgeband is cooled to solidify its shape. It may also pass through a calibration system to ensure its dimensions meet the desired specifications.

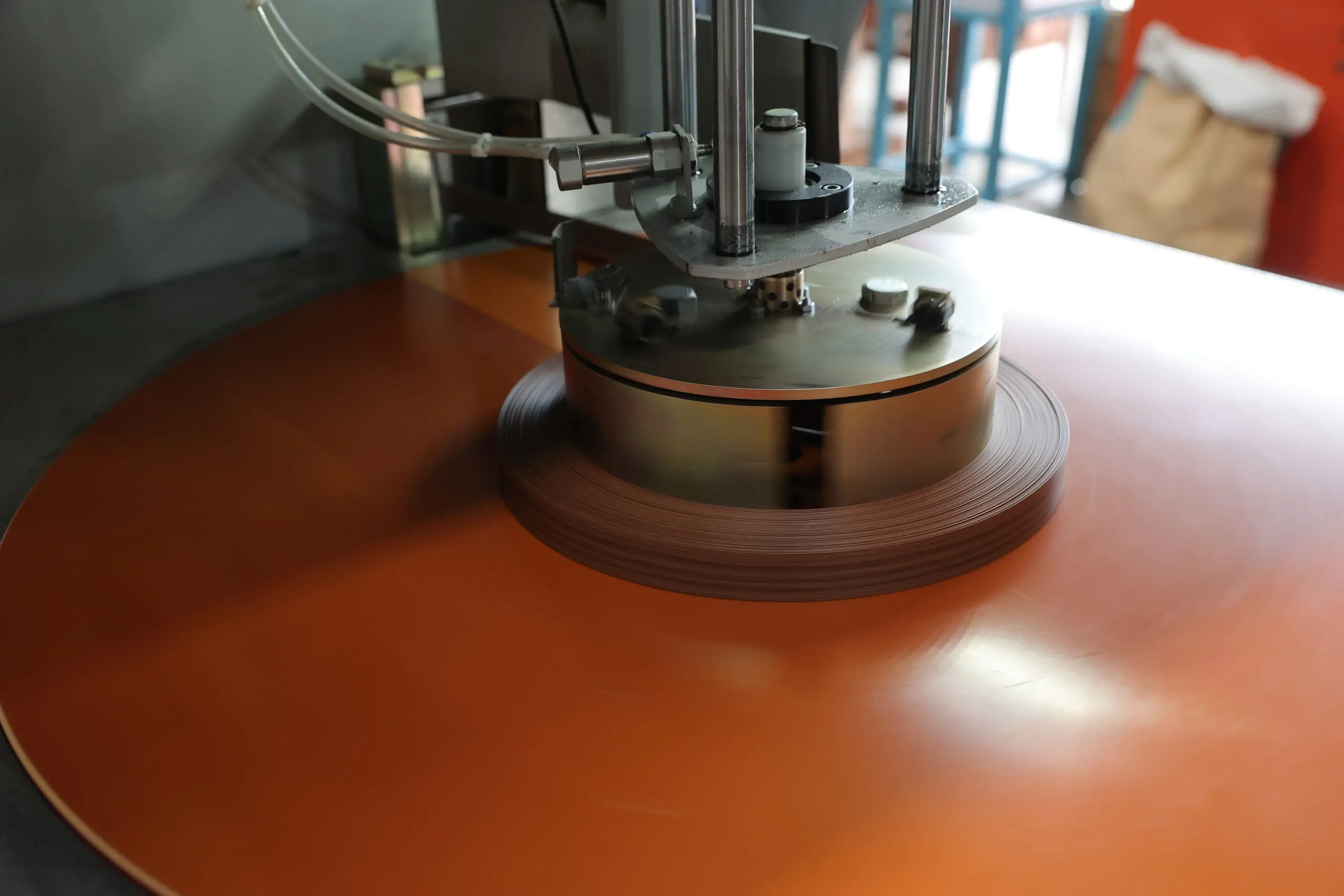

Some PVC edgebands are printed with patterns or wood grain designs to mimic the appearance of natural wood. This step can be done during the extrusion process or as a separate printing step.

Throughout the manufacturing process, quality control checks are performed to ensure that the edgeband meets the required standards for colour, thickness, texture, and other properties.

Our manufacturing expertise extends to an infinite range of tones, hues, and patterns, ensuring a perfect match.

At E3 Edgeband Firm, our team of core technicians brings over two decades of unmatched expertise to the table.

We aspire to create edge banding solutions that are synonymous with precision, durability, and flawless finish.

Our mission includes leading the edgebanding industry in sustainable manufacturing and sourcing.

At E3 Edgeband, we are committed to maintaining a dynamic approach to research and development, driven by the rapid technological advancements and evolving customer preferences within the realm of design and trending fashion of architecture industry. Our proficient team of experts firmly believes that innovation is an ongoing process. It extends beyond merely introducing new products and shades into our existing portfolio, it encompasses the constant refinement and enhancement of existing offerings. At E3 Edge Band, market research plays a pivotal role in our commitment to staying attuned to emerging trends, design evolution, changing client preferences, and demand dynamics. Our dedicated Research and Development team is devoted to crafting novel product combinations, all with the ultimate goal of elevating client satisfaction.

They stand among the most reputed edgeband manufacturers in the industry. Their largest production facility, spread across more than 2 lakh square feet in Greater Noida, Uttar Pradesh, boasts a daily capacity of 10 lakh meters. With endless options in tones, textures, patterns, and customizable colors and sizes, their strong network of dealers, distributors, and warehouses ensures smooth supply across India.

Location: Noida [ Uttar Pradesh ]

Location: Hindupur [Andhra Pradesh]

Delhi | Noida [UP] | Maharasthra | Karnataka | Madhya Pradesh | Gurgaon [Haryana]