When finishing plywood furniture, one big question pops up—should you use plywood banding or solid wood edges? Both have pros and cons, but the right one depends on durability, aesthetics, and cost.

Plywood edge banding gives a seamless modern finish, and solid wood edges give a touch of natural beauty and strength. But which one is the winner? Whether you’re a carpenter, interior designer or DIYer, understanding differences will help you make an informed decision.

Here, you can see the pros and cons to get a better idea of which one to choose for your furniture.

Understanding Edge Banding for Plywood

Plywood edge banding is the finishing touch that covers the raw edges of plywood, giving your furniture a clean, polished look. That’s because plywood has multiple layers, and those raw edges can be rough. Edge banding tape for plywood adds looks and protects against moisture as well.

Role of Edge Banding Tape for Plywood in Finishing

Edge banding tape is a simple, effective way to elevate plywood furniture to the next level. It provides a seamless finish, protection against chipping and wear, and a cost-effective alternative to solid wood edging.

You can use a variety of materials for plywood banding:-

- There’s PVC edge banding, which is affordable, flexible and moisture-resistant.

- Wood veneer edge banding gives you a natural wooden finish.

- Melamine edge banding comes in different colours and patterns.

- ABS edge banding is eco-friendly and impact-resistant.

What is Solid Wood Edging?

Solid wood edging is a different story. Attaching a thin strip of genuine wood to the edges of plywood blends in with your wooden furniture, providing strength and durability. It requires more work, such as glueing, clamping, and sometimes additional finishing. On the other hand, edge banding tape for plywood makes it easier to get that same look.

How It Differs from Plywood Edge Banding

|

Feature

|

Plywood Edge Banding

|

Solid Wood Edging

|

|---|---|---|

|

Material

|

Veneer, PVC, ABS, melamine

|

Real solid wood

|

|

Durability

|

Moderately durable

|

Highly durable

|

|

Aesthetics

|

Modern, sleek finish

|

Natural wood appearance

|

|

Application Method

|

Heat or adhesive tapes which are stronger

|

Glued

|

|

General Cost

|

Lower

|

Expensive

|

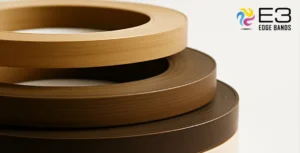

Plywood Edge Bands

Selecting the perfect edge band tape is key to the durability and aesthetics of furniture. With various materials, colours, textures and adhesives available, choosing the right one ensures long-lasting performance and a seamless finish.

Here’s what to consider:-

Pros

Plywood edge banding is the most inexpensive way of finishing plywood furniture. Which comes without sacrificing style. Unlike solid wood edging, which can be time-consuming and expensive, edge banding tape offers a pocket-friendly alternative.

One of plywood’s biggest benefits is its ability to create a sleek, uniform look. That uniformity is due to its ability to cover the rough edges of plywood, making the final product look polished and professional. Edge banding is available in multiple colours and textures to match any furniture style.

Applying edge banding tape—whether heat-activated or adhesive-backed—is relatively simple. That simplicity is part of its appeal for DIY enthusiasts and professionals who want a quick, efficient solution for finishing furniture. Heat-activated or adhesive-backed tape makes the process even easier.

Cons

Plywood edge banding has the drawback of being less durable than solid wood. Wooden edge banding makes plywood look better, but it might not be as sturdy as solid wood edging. Heavy use and impact exposure can accelerate its deterioration over time.

Furniture edge banding tape may begin to peel or chip if not applied correctly or if the adhesive deteriorates over time. To guarantee longevity, appropriate application and routine maintenance are required.

Solid Wood Bands

Solid wood adds a premium natural wood finish appeal to plywood furniture, improving its look. Making it an excellent choice for luxurious interiors because, unlike plywood edge bands, it merges perfectly with solid wood furniture.

Better Sturdiness

Solid wood edging is sturdier and more durable than wood edge tape. It is perfect for furnitures subjected to heavy use because they are more resistant to dents, chipping and damage than plywood.

Sandable and Refinishable

Solid wood edging, unlike furniture edge banding tape, can be refinished, stained, or sanded to accommodate changing design tastes. Over time, this adaptability makes restoration and customisation simple.

Cons

Solid wood edging is more expensive than plywood due to material costs and additional labour needed for installation. It also requires more time and effort because it requires cutting, glueing, and clamping.

Wood is a naturally occurring substance that responds to variations in temperature and humidity. In contrast to wooden edge banding or edge banding tape for plywood, solid wood edges can expand or contract over time, resulting in warping or cracks.

How Plywood Edge Banding Stands Out!

Sandable and Refinishable

Cost is an important factor when trying to make up the mind to use plywood edge banding rather than wooden banding. Solid wood edging is costlier, because it requires more time, hard work, and materials.

Simple to Use

Plywood edge bands are easier to install than solid wood edging, which requires careful cutting, glueing, and clamping. To get a polished seamless finish, you only need an iron or edge banding machine with wood edge tape.

Smooth and Contemporary Style

Plywood provides a smooth, consistent like appearance for those seeking a modern, clean, sleek look. It blends in perfectly with different furniture designs and removes the jagged edges of plywood. Because it comes in multiple finishes, it is easily compatible with different interiors.

Sturdy and Wear-Resistant

Modern plywood edge bandings are made to resist everyday wear and tear despite some believing that wooden banding lasts. For furniture that beats time, options like PVC and ABS edge banding are perfect because they resist moisture and don’t chip.

E3 Group: Setting New Standards in the Industry

E3 Group is a manufacturer that provides a wide variety of high-quality products, such as laminates, MDF, ACP, clads, plywood edge banding, PVC edge banding, and even abs edge banding tape.

For orders and queries, you can contact us directly or visit our website. We are also available nationwide, connecting audiences and valuable customers via our social media handle.