Ever curious if PVC edge banding tape is heat and moisture-resistant? Whether you’re building kitchen cabinets, office furniture, or wardrobes, durability always comes first—especially in heavy-use or humid applications.

That’s when the water-resistant and heat-resistant properties of PVC edge tape truly shine. Many people think all edge bands are created equal, but they’re not.

In this blog, we’re going behind the scenes of PVC edge banding—how it handles heat and water and why it’s a favourite among modular furniture.

What is PVC Edge Band?

PVC edge tape is a polyvinyl chloride (PVC) finishing strip that covers exposed furniture board edges like plywood, MDF, and particle boards. It is more than a cosmetic trim—it protects surfaces against moisture, impacts, and daily wear and tear.

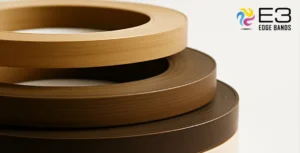

This tape is usually used in modular furniture such as wardrobes, kitchen cabinets, office tables, and storage cabinets. It comes in various textures, finishes, and thicknesses, which offer functionality as well as beauty.

Ranging from matte to high gloss, PVC edge banding tape offers strength in addition to matching the overall surface design.

E3 is a popular name in this sector, providing best-in-class PVC edge band tape that can be applied to laminates, HDMR, and clads—ensuring uniform design consistency on all furniture surfaces.

Is PVC Edge Banding Tape Heatproof?

Yes—PVC edge band is heat-resistant, but the level of heat resistance will depend on the quality and composition of the tape. Standard PVC edge bands can typically withstand temperatures of around 50–70°C. These are suitable for most indoor uses. But premium edge bands, particularly those with a high gloss PVC edge banding finish, will be more heat-resistant—perfect for areas which are subject to constant heat.

Consider kitchen shutters where steam from cooking is normal, or office chairs by windows with full sun exposure. In such real-life situations, good-grade tape prevents edges from peeling, warping, or becoming yellowed with age.

The most prevalent myth is that all PVC tapes are heat-sensitive, but they are not. Good manufacturers such as E3 employ heat-stable formulas that withstand durability tests even under the toughest conditions.

Is PVC Edge Banding Tape water resistant?

Yes! One of the greatest advantages of PVC edge banding tape is its higher moisture resistance. Unlike wood-based edge bands, which will swell, warp, or peel when exposed to moisture, PVC edge band tape remains constant and sealed. Its non-porous nature prevents water from being absorbed, making it a great choice for spaces that experience excessive humidity.

This is precisely the reason why it’s a favorite for kitchen drawers, bathroom cabinets, and wardrobes, where spills and steam are routine. High-quality tapes, like those offered by E3, also exhibit strong adhesion to the panel surface—even after repeated exposure to water.

In water spill tests, PVC edge banding tape outperforms standard wood edge bands hands down, making your furniture not only attractive but also more durable in harsh conditions.

Technical Highlights of PVC Edge Banding Tape

| Feature | Details |

| Material | Polyvinyl Chloride (PVC) |

| Heat Resistance | 50–70°C (Standard) / Up to 85°C (Premium) |

| Water Resistance | 100% moisture-resistant |

| Thickness Range | 0.4 mm to 2 mm |

| Width Range | 12 mm to 45 mm (custom sizes available) |

| Finish Options | Matte, Suede, Textured, High Gloss PVC Edge Banding |

| Bonding Strength | Strong adhesion with hot melt glue or laser bonding |

| Flexibility | High – suitable for curved or contoured furniture edges |

| Applications | Kitchen cabinets, wardrobes, office desks, bathroom vanities |

| Durability | Scratch-resistant, UV-stable, long-lasting edge protection |

| Color Matching | Available in exact matches with laminates, clads, and HDMR (E3 Collection) |

| Eco Certifications | RoHS compliant, Lead-free |

What Influences Performance?

PVC edge banding tape is as much about the product as it is about application. Material thickness, adhesive quality, and application process are three important factors that have an effect on overall performance.

Broader edge bands tend to provide increased impact strength, while narrower ones can be suitable for small applications. The glue is important as well. Fine heat-activated adhesives provide long-lasting holding, and hot-air tools give seamless, invisible joints—perfect for today’s high-gloss finishes.

The second key feature is application conditions—and this is where E3 Edge Band excels. Specifically designed for Indian climatic conditions, E3 makes sure its edge bands neither peels, nor bubbles, nor darkens even at extreme temperature or humidity.

How to Select a Good PVC Edge Banding Tape?

Since there are so many available in the market, selecting the right tape is not easy. But if you know what to look for, it is simpler to separate the best from the rest.

Here is a simple checklist which will assist you:-

Thickness: Utilize 0.8 mm to 2 mm tape depending on application for permanent strength.

Flexibility: A suitable pvc edge band tape should fold around corners without breaking.

Finish: Choose matte, texture, or high gloss based on your panel surface.

One of the least emphasised—but most important—details is finish matching. Regardless of whether you are using laminates, HDMR, or clads, your edge banding must match colour and finish exactly. Mismatch will ruin an otherwise high-end design.

We at E3 are different—offering a broad selection that perfectly matches E3’s laminates, clads, and HDMR boards. That way, your furniture is not only functional but also looks perfect—edge to edge. Our PVC Edge Banding Tape Price is relatively affordable and available in different thicknesses, roll size, design, shades, and textures.

Why E3 Edge Banding Tapes Stand Out?

When you are choosing the best PVC edge banding tape, E3 is the one that leads the way—designed with Indian conditions, imagination, and expertise at its core.

The only thing that truly sets E3 apart is its flawless colour matching. Whether using clads, HDMR boards, or laminates, E3 guarantees that all edges will match in colour, shade, and texture. From matte to high gloss PVC edge banding, the finish is flawless and consistent.

With improved adhesion, strength, and high design flexibility, E3 offers a complete edge solution that unites performance and appearance.