That silky-smooth finish along your furniture edge? It’s not all cosmetics—it’s earning its keep. Edge banding tapes are the behind-the-scenes stars of today’s furniture-making, locking in strength while serving up style. But one nagging question is still out there: Are they durable?

From kitchen steaming to everyday bumps and bruises, edge bands take the hit. Homeowner, interior designer, or manufacturer—no matter who you are, knowing about their long-term performance is critical. In this blog, we’ll dissect what makes edge banding tapes durable, what material holds up stronger, and how to keep your edges looking flawless for decades.

So, if you’re spending money on style and durability, this is your best guide to longevity for edge banding.

What Are Edge Banding Tapes?

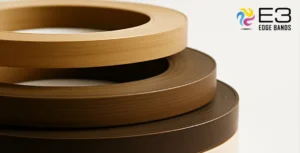

Edge banding tapes are thin strips that cover the exposed edges of furniture or panels, usually made of wood, engineered wood like MDF, or plywood. They provide a neat, finished appearance while protecting the raw edges from wear and tear. These tapes create a smooth transition between surfaces, providing aesthetic pleasure and durability.

Materials Used (with Special Emphasis on PVC Edgeband Tapes):

Edge banding tapes are available in different materials, each selected for specific performance characteristics. The most used materials are:

- PVC (Polyvinyl Chloride): Flexible, rugged, and versatile, PVC edge tapes are among the favorites. They provide high resistance against moisture, scratches, and heat and are suitable for use in kitchens, offices, and foot-traffic zones.

- ABS (Acrylonitrile Butadiene Styrene): A bit stiffer material, ABS edge banding provides a shiny finish but tends to be more costly.

- Melamine: A paper material coated with melamine resin, commonly utilized for aesthetic finishes.

Aside from the aesthetic value, edge banding also has a protective function. It protects the edges from physical harm, such as chipping and scratching. The smooth surface of edge banding PVC tape beautifies the furniture and keeps moisture and dust from penetrating the raw edges, maintaining the integrity of the material.

Factors That Affect Durability

The longevity of edge banding tapes is based on several important factors. Knowing these factors will enable you to select the most suitable one for long-term, high-performance outcomes.

Material Quality

The material’s quality for edge banding is essential for its durability. Here’s a comparison of the most used materials:

- PVC (Polyvinyl Chloride): PVC edge tape is widely used because it is strong and flexible. It is also resistant to wear and tear, water, and impact, making it perfect for busy places like kitchens and offices.

- ABS (Acrylonitrile Butadiene Styrene): Slightly stiffer than PVC, ABS gives a high-gloss appearance but is more susceptible to cracking due to stress. It’s acceptable for use in decorative applications but may not stand up to daily use, and neither is PVC edge tape.

- Acrylic: Acrylic edge banding is recognized for its appearance, giving a glossy finish. Yet, it may be more delicate and less tolerant of environmental conditions than PVC.

- Melamine: Melamine edge banding is economical and long-lasting but less impact-resistant than PVC. It’s commonly used in low-cost applications but might not hold up as well under extreme conditions.

Environmental Exposure

The performance of edge banding tapes relies heavily on where they are used:

- Moisture: High-humidity or water-exposure areas (such as bathrooms and kitchens) may accelerate the degradation of edge banding, particularly if the material is not sealed.

- Heat: Direct exposure to heat, such as from too-hot appliances or sunshine, can gradually make the edge banding go soft or peel off. Heat tape made from PVC is not prone to burning, but continued exposure to severe temperatures can weaken it.

- Durability: High-traffic surfaces or surfaces subject to frequent contact, such as cabinet doors or furniture, impose greater stress on edge banding. Heavy-duty choices such as PVC edge tapes can withstand such wear better than others.

Adhesive Performance Over Time

Adhesive in edge banding tapes is a determining factor in edge banding durability over time. A good-quality adhesive ensures the banding to stay firmly attached, even with harsh conditions. With time, exposure to heat, water, or mechanical wear may deteriorate the bond, resulting in the peeling or lifting of the tape. This is why it is important to select PVC edge tape with a firm, long-lasting adhesive that resists loosening over time to achieve a more enduring, impeccable finish.

Why E3 Edge Banding Tapes are Different

When it comes to edge finishing, not all tapes are equal. E3 Edge Banding Tapes excel beyond mere functionality to provide unparalleled durability, aesthetics, and performance. From designing stylish wardrobes to high-traffic kitchen cabinets or sleek office furniture, E3’s PVC edge tape provides lasting, perfect edges.

Our edge banding PVC tape is designed to withstand moisture, wear, and everyday use — making it an intelligent option for residential and commercial interior applications. From the minimalist sophistication of solid series edge banding to the luxurious texture of Soft Touch Edgeband, the collection features:

1. Fluted Edgeband

Fluted edge bands have finely grooved textures, providing a 3D visual effect to furniture edges. Suitable for high-end designs, they improve grip as well as looks. They are frequently used in contemporary wardrobes and focal cabinets.

2. Soft Touch Edgeband

These edge banding tapes have a matte, velvety texture with a smooth finish. They provide a classy, fingerprint-proof finish for high-end interiors and sleek designs.

3. ABS Edge Bands

Fabricated from Acrylonitrile Butadiene Styrene, these tapes are hard-wearing and impact-resistant. Unlike PVC, ABS is more environmentally friendly and an ideal substitute for eco-friendly projects.

4. uPVC Edge Bands

uPVC edge banding PVC tape is unbeatable in terms of durability and flexibility. Chemical and moisture-resistant, they’re perfect for the kitchen, bathroom, or high-traffic zones.

5. Acrylic Edgeband

These tapes have a glass-like high-gloss finish and are commonly used to replicate lacquer finishes. Acrylic edgebands are UV-resistant and retain clarity and shine in the long run.

6. Solid Series Edge Banding

The solid series edge banding tapes are available in uniform, non transparent finishes that are ideal for impeccable modern designs. They perfectly match with panels and laminates, providing a unified and sleek look.

Are you ready to design your furniture with unparalleled precision and style?

Contact E3 Edge Bands today and discover our high-end lineup of edge banding tapes where design meets durability.